Ondrives Ground Spiral Bevels

The Gleason Phoenix 280G is a significant leap forward in gear-machining technology and establishes a new benchmark for bevel gear grinding for gears up to 280mm in diameter. Ondrives are able to offer entirely goround ranges of spiral bevel, hypoid, high ratio hypoid (HRH) offset spirals. Increased stiffness and higher part quality in this extremely accurate machine is due to the high rigidity of the newly designed polymer concrete column style frame. Thus achieving very high thermal stability and damping characteristics. The 280G’s automatic stock divider, mounted in close proximity to the work spindle, helps ensure consistently high gear quality. The unit automatically determines the tooth slot position of the pre-finished gear to provide accurate and reliable stock division, helping eliminate operator errors. |

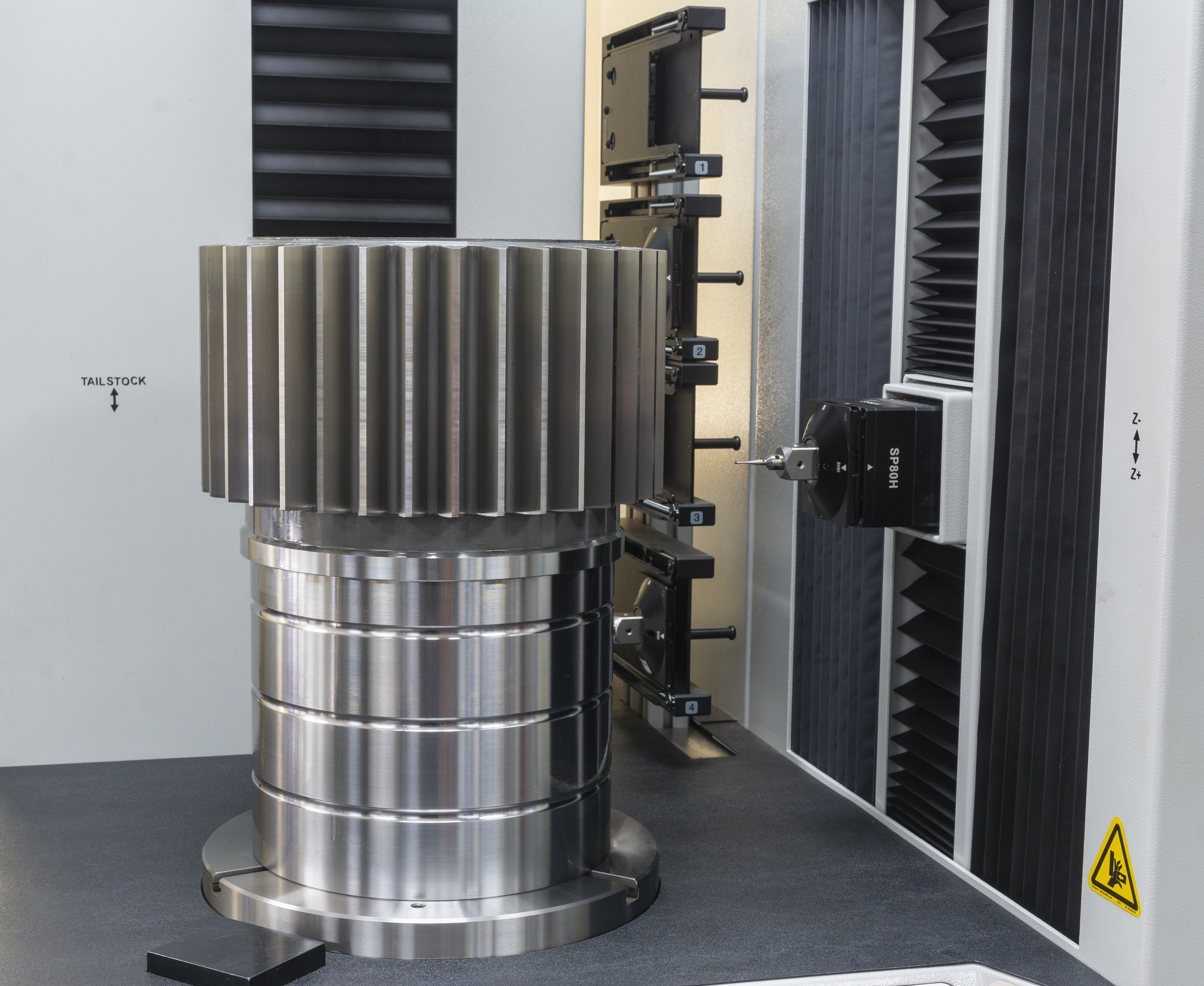

To compliment the 280G Ondrives also purchased the 475GMS gear inspection machine. Offering some of the latest technologies in the field, including four-axis design, generative motion, state-of-the-art 3D scanning probe systems, linear drive motors and Gleason Metrology Systems GAMA software. The accuracy of the 475GMS is certified via the ISO17025 and A2LA® quality systems adopted by Gleason Metrology Systems and meets VDI/VDE 2612/2613 class 1 specifications. |

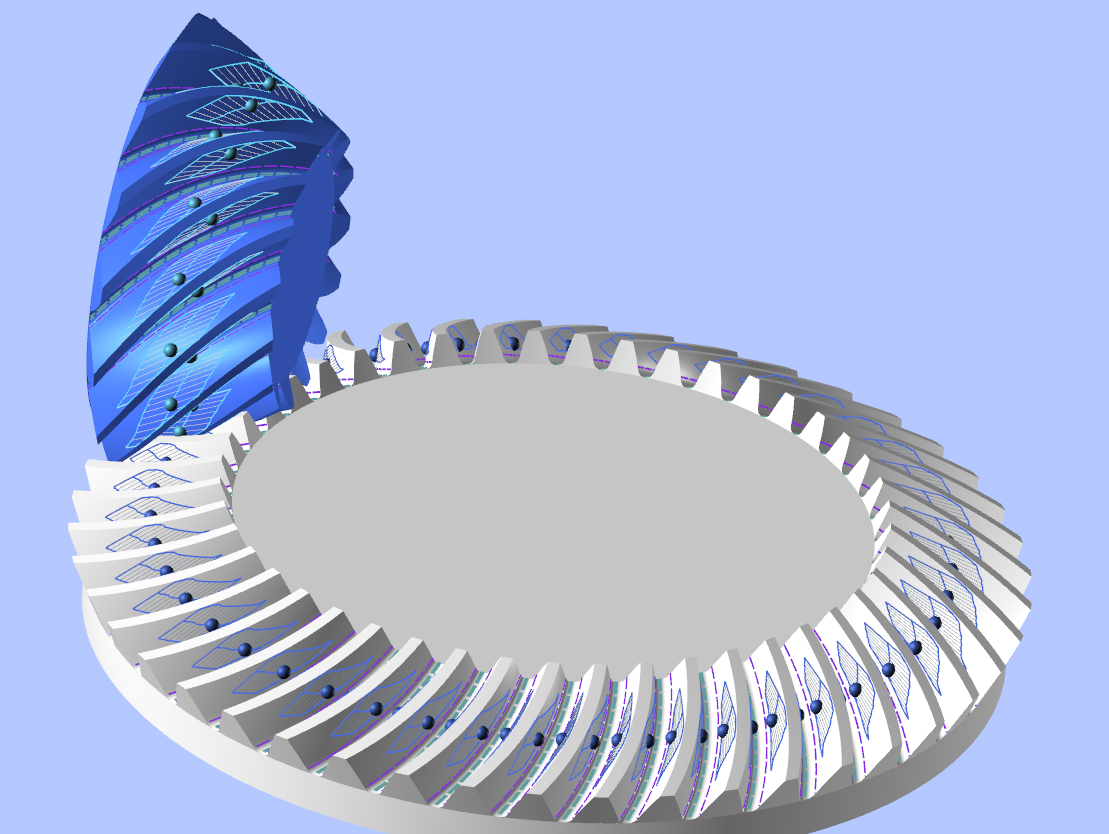

To maximise the full potential of both these highly accurate machines by incorporating the Gleason software CAGE™ (Computer Aided Gear Engineering) in a closed loop system enables ondrives to produce both designs and products with optimum tooth contact analysis (TCA) and Loaded tooth contact analysis (LTCA). |